Manufacturing Execution System

Through our esteemed partnership with Fortech LLC, a distinguished USA-based company, we are proud to offer manuFACT™ Line Event Data System (LEDS) a manufacturing Execution System (MES) designed to enhance productivity through systematic and proactive quality and efficiency enforcement. By offering powerful tools and key performance indicators (KPIs), manuFACT™ aids in increasing efficiency and reducing downtime in manufacturing operations globally.

LEDS MES connects live production information from equipment across multiple plants, integrating with enterprise business applications to provide visibility, control, and optimization of production processes enterprise-wide.

LEDS MES connects live production information from equipment across multiple plants, integrating with enterprise business applications to provide visibility, control, and optimization of production processes enterprise-wide.

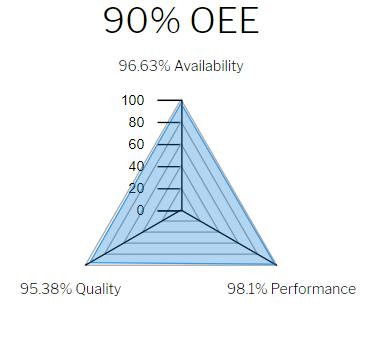

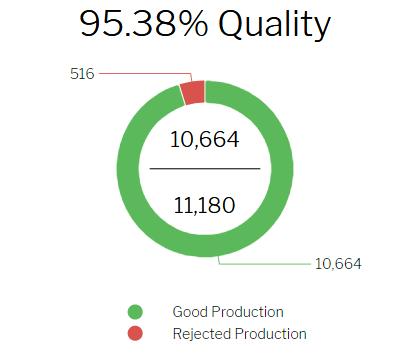

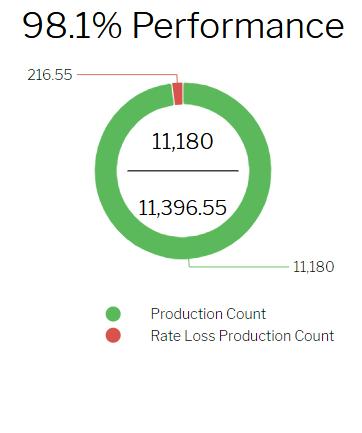

OEE Dashboard Display

The Dashboard Display offers a real-time overview of Overall Equipment Effectiveness (OEE), breaking it down into Quality, Availability, and Performance metrics.

Key Features:

- Comprehensive OEE Tracking:

- Real-time monitoring and detailed breakdown of OEE

- Intuitive User Interface:

- Easy-to-read graphics with straightforward calculations

- Real-Time Data Visualization:

- Immediate access to live production data and insights

Benefits:

- Increased Efficiency:

- Streamlined operations and quick decision-making

- Improved Productivity:

- Optimal production levels and reduced delays

- Higher Quality Products:

- Proactive quality management for consistent high-quality output

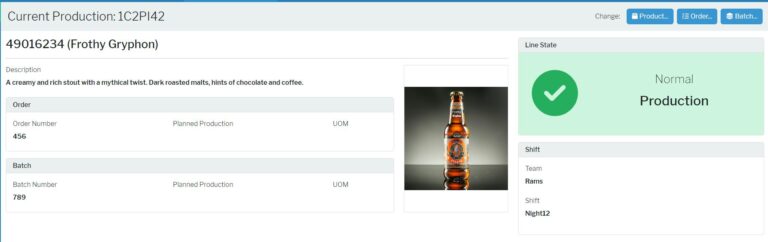

Line Production

Line Production LEDS provides detailed insights into production, output volumes, and efficiency through real-time tracking and visualizations.

Key Features:

- Line Production Tracking:

- Monitor production states and output in real time

- Enhanced Production Oversight:

- Analyze efficiency and identify bottlenecks

Benefits:

- Improved Productivity:

- Maintain optimal production and reduce delays

- Higher Quality Products:

- Fewer defects with proactive quality management

- Cost Savings:

- Lower production costs and optimized resource use

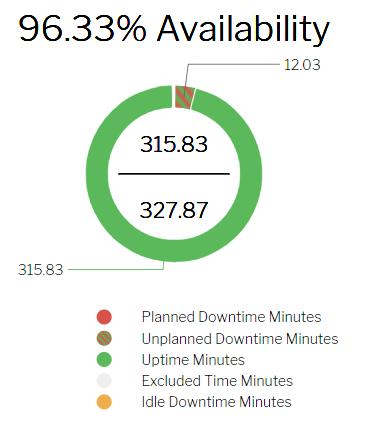

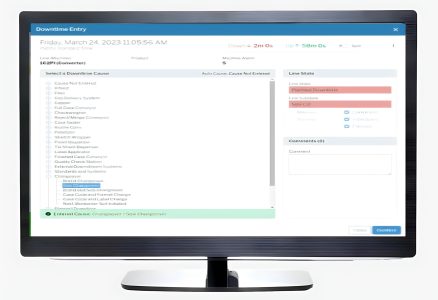

Reliability (Downtime)

Reliability (Downtime) LEDS ensures continuous production by accurately tracking and analyzing downtime events.

Key Features:

- Downtime Tracking:

- Monitor and log downtime events with detailed analysis

- Availability Insights:

- Real-time tracking of machine uptime and downtime

Benefits:

- Reduced Downtime:

- Efficient maintenance scheduling and improved machine reliability

- Cost Savings:

- Lower costs through enhanced efficiency and reduced waste

- User Empowerment:

- Actionable insights for operators and managers

Reporting and Data Analysis

Reports LEDS offers robust reporting capabilities, providing comprehensive insights into KPIs, real-time production data, and detailed downtime analysis. These reports support quick decision-making and proactive quality management.

![report {"remix_data":[],"remix_entry_point":"challenges","source_tags":["local"],"origin":"unknown","total_draw_time":0,"total_draw_actions":0,"layers_used":0,"brushes_used":0,"photos_added":0,"total_editor_actions":{},"tools_used":{},"is_sticker":false,"edited_since_last_sticker_save":false,"containsFTESticker":false}](https://trueconceptltd.com/wp-content/uploads/elementor/thumbs/report-qq4mjv8mvzvcr8x69ck7at1rh5anel475upj9j6t4w.jpg)

Additional Modules

-

- CIL (Clean Inspect Lube):

- Structured maintenance procedures to prevent breakdowns and extend equipment life

- Activity Scheduler:

- Efficient scheduling of various MES tasks to improve workflow

- Alarms:

- Real-time notifications for system health issues to prevent disruptions

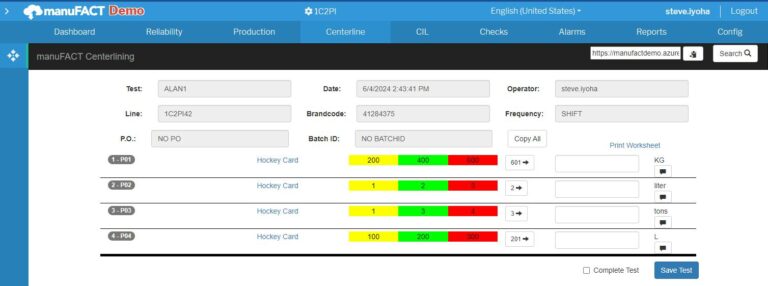

- Centerline:

- Monitoring and maintaining optimal process parameters for consistent product quality

- CIL (Clean Inspect Lube):